Service

ARA has a highly skilled and experienced engineering team who specialize in designing and installing instrumentation in complex structures and assemblies to measure forces, moments, pressures and temperatures. Our team is also capable of diagnosing and repairing instrumentation faults.

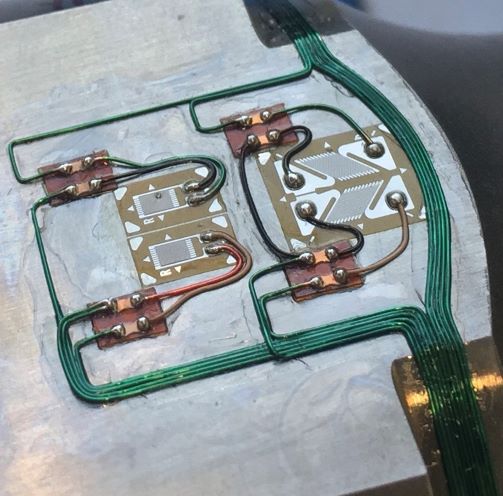

Our instrumentation team are experienced at installing and testing Wheatstone Bridges and Platinum Resistance Thermometers (PRTs) for highly stressed and dynamically loaded applications with severe space restrictions. Our thermal matching techniques make carefully tuned adjustments to instrumentation wiring in order to minimize the effect of thermal variation on the measured electrical outputs.

We also have experience of working with semi-conductor gauges, in particular diagnosis and repair of force measurement systems which use this type of sensor.

We can install instrumentation to measure both static and unsteady pressures including:

We can also install instrumentation to measure both steady and unsteady orientation of equipment:

All of our individual sensors and instrumented assemblies are calibrated onsite at ARA with all results traceable to national standards.

Our instrumentation systems are designed for use with real time data acquisition and monitoring – including stress monitoring. We use what we create in our own onsite test facilities, including our Transonic Wind Tunnel, where the safety of the systems and equipment under test is of critical importance.